|

| |

Job #5909

Removal of Goretex vent fixture

The fixtures are Marelon or some other plastic that Epoxy

does not bond to, and - unlike Chinook fixtures that have some grooved pattern

on their bonding surface - these are generally left plain, so they tend to come

adrift, and LEAK

|

|

vent fixture loose from underside of

deck and leaking |

|

|

deck opened up to allow removal of

fixture |

|

|

prying out the fixture |

|

|

evacuating |

|

|

making an undercut for the "lid" |

|

|

"lid" cut from 1/8" PVC foam, with waxed string to aid

manipulation (I want the Divinny lid, because the Urethane, while it forms a

nice crust, often has large-ish holes inside, so the cut surfaces are

usually not ready for glassing, and I did not want to have to mess with

filling) |

|

|

trial-fitting the "lid" |

|

|

2-part Marine Urethane poured into the cavity, "lid"

slipped in place REAL quick and held there until expanding foam holds it in

place. Remove string before it all sets up hard! |

|

|

all cleaned up and ready for top skin |

|

|

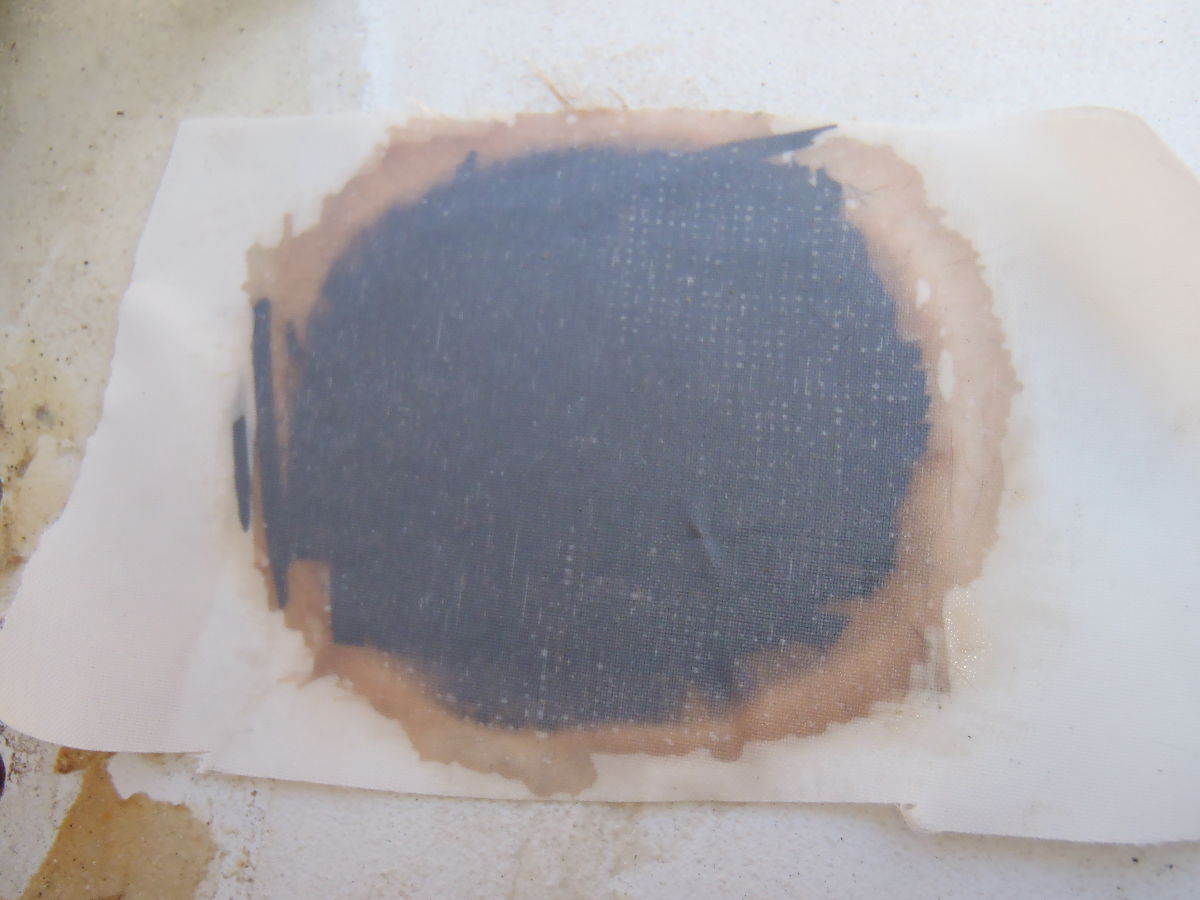

glass/Carbon cloth/glass, with a layer of peel ply to

smooth things out (the reddish color is from the Epoxy hardner which has sat

around a while and absorbed moisture) |

|

|

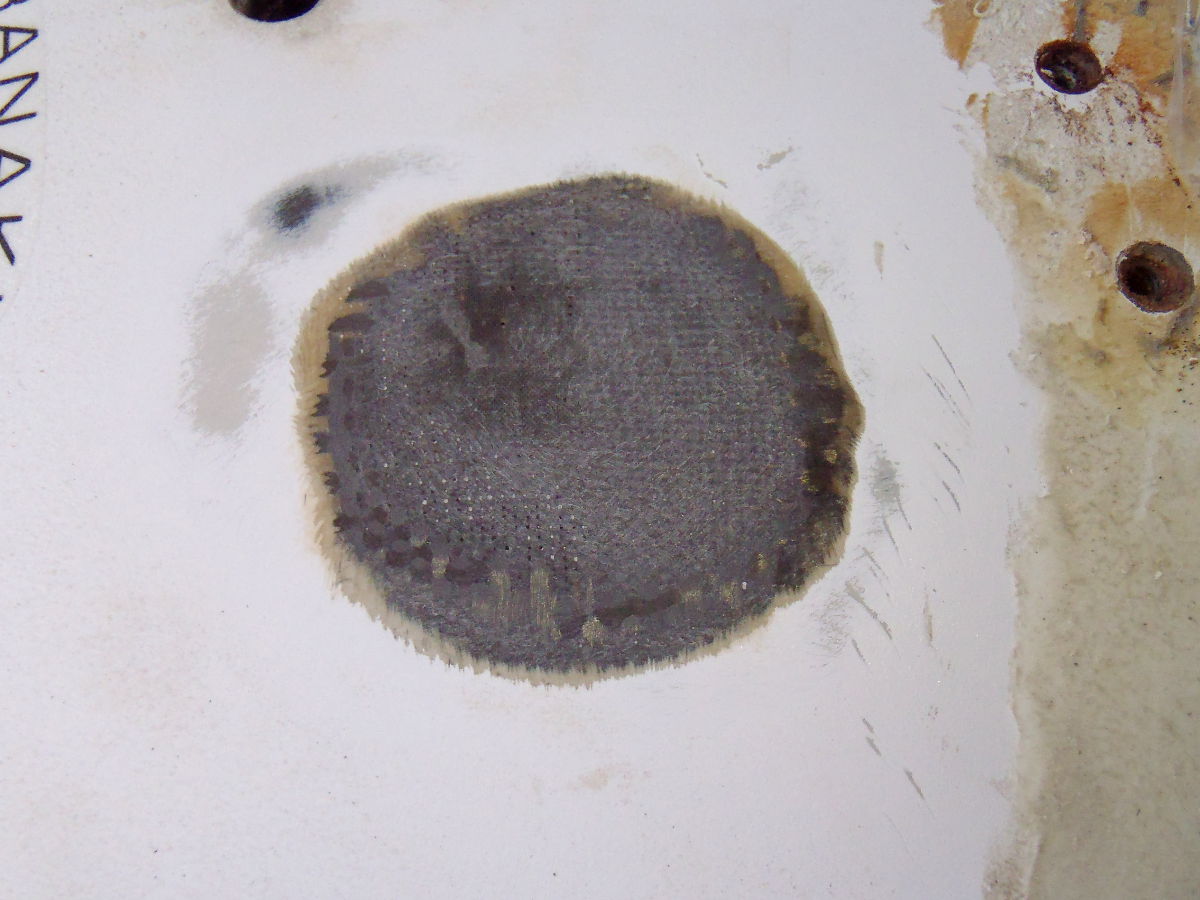

edges feathered out - to prep for paint, all that's

required is to fill those pinholes with spotputty Acrylic glaze |

|

|

painted, and Deck Dust sprinkled into the wet paint |

|

|

for the retro plug installation, I scratch all contact

surfaces to improve the bond; and tape off all around, to prevent messes |

|

|

all the resin cleanup happens on the tape, rather than

the board's non-skid, from where it would be near-impossible to remove |

|

|

ready to roll |

|

Return to assorted repairs |

|