Anatomy of an Epoxy Sandwich board

Cores are Styrene-based foams, commonly (and erroneously)

referred to as "Styrofoam", either beaded (the majority, bigger

boards have vent screws), or extruded (a bit heavier). Throughout this site, I

will refer to this material as "EPS", expanded polystyrene, and "XTR",

extruded polystyrene foam.

Because EPS and XTR foams melt with exposure to Styrene, boards

are put together with an Epoxy, most of which have no solvents. Painted boards

use "normal" Epoxies, while clear-finished boards use (or should use)

UV-resistant Epoxies. There are many different Epoxy formulations for special

applications. Most repair jobs will use room-temperature-cure. All Epoxies have

a very specific mixing ratio of resin to hardener, and deviating substantially

from this mixing ratio will make for a gooey mess. Unlike Polyester resins, which

can be accelerated by adding more catalyst, Epoxy resins can only be accelerated

by using a faster hardener (or by heating them - but that's a different story).

Reinforcements (the stuff that provides the strength) are

either fiberglass of some type or another, or Carbon, or KevlarŪ, or combinations

thereof. Fiberglass is an all-around material that does nothing particularly

well, but has no glaring shortcomings, either. Carbon is enormously stiff for

its weight, but quite weak in impact. KevlarŪ handles impacts extremely well, but

is an utter pain to work with. All these reinforcements come in a variety of

arrangements, from random chopped-strand-mat, to woven cloths, to

unidirectional tows. Some combine different raw materials, to tailor the

composite to best handle particular loads.

To improve panel stiffness (decrease heel denting and

such) most boards these days have some sort of sandwich structure. This will

consist of either a linear or cross-linked PVC foam (Airex or Divinycell,

respectively), or wood veneer inserts, or a combination thereof. A cheap

substitute is Coremat, a blanket-like material that absorbs much resin to gain

bulk and stiffness. I don't see many boards with it anymore. Honeycomb cores

were en vogue for a while, but have - fortunately - fallen from favor

recently, due to their propensity to take on prodigious amounts of water.

Where major local loads need to be accommodated, all

boards have (or should have) inserts surrounding the fixtures. These inserts are

commonly made from Divinycell or high-density Urethane foam.

Finish is either resin (most commonly a Polyester finish

resin - beautiful gloss but chips easily), or paint (Epoxy paints are most

common in production boards, while customs usually have Linear Polyurethane

paints - tough and long-lasting), or ASA plastic skin (heavy and not

particularly attractive,

but takes major abuse gracefully)

|

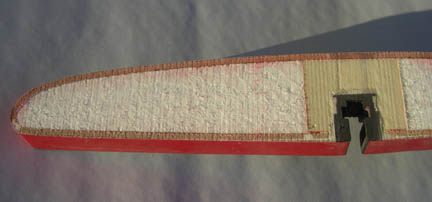

Current state-of-the-industry: EPS foam

core, inner glass, Divinycell, outer glass, paint. Fancier boards

substitute Carbon, and may throw in some veneer, but basically, this is what

most good Epoxy sandwich boards look like these days, be they surf,

windsurf, or kiteboards..

Observe the high-density Urethane block supporting the

fin box |

|

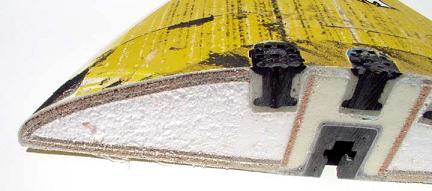

Double PVC sandwich for tough applications -

this one a JP high wind sailboard |

|

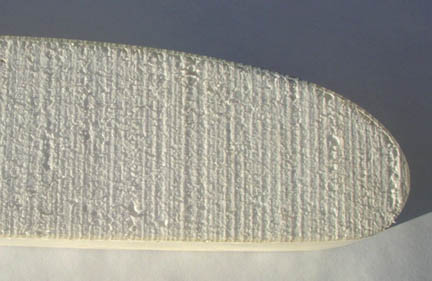

Nicely engineered custom Formula

windsurfing board: varying thickness and density sheet foam to match local

loads, Carbon reinforcements |

|

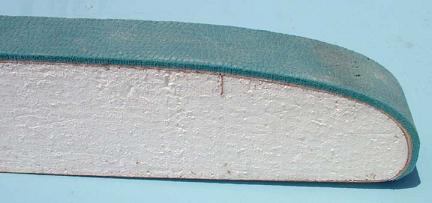

Surftech wood veneer board: EPS foam core,

inner glass, structural wood veneer. Strong and

gorgeous! |

|

Honeycomb in the bottom, some sort of

Coremat-like stuff on the decks. These boards had enormous problems due to

the discontinuities produced by the snazzy recesses for padz and such |

|

And a few non-sandwich Epoxy boards |

|

Economy construction: non-woven

fiberglass reinforcements (usually with a token unidirectional strand thrown

in someplace), with tough ASA skin. Ideal for rentals and such, but heavy

and lacking stiffness. |

|

Surftech Softop. EVA foam padding

distributes deck loads, making for a fairly dent-resistant single-skin

construction. Strong and

tough while relatively light - favorites with rental places. |

|

One of the many new single-skin

fiberglass over EPS core boards. I don't get it - all the extra cost and

vulnerabilities of Epoxy, with mechanical properties worse than the

old-fashioned glass board. At least those did not soak up water... |

|