| Adding

Foot Strap Inserts - the Basics |

|

The Bits: Chinook 5-hole

inserts cut down to the desired (in this case) 3-hole size. Bits of 3/8"

Divinycell cut to size (cuts easily with utility knife). Paste of Epoxy

thickened with Q-Cells to hold it all together. |

|

The fun begins: think of

this as making sandwiches - "butter up" the slabs of

Divinycell, squoosh in the insert as "filling", butter up more bits of

Divinycell to complete the assembly. |

|

After the "sandwiches" have

cured, they need to be trimmed nicely to facilitate installation. Easiest

way to get things square is to use a bandsaw, bench grinder, or both. |

|

Mark the insert locations

(hole spacing anywhere from 6 1/4" for small feet, to 7" for big ones with

booties). The Pleskunas guide is one of the

handiest tools to have around the shop! I get mine from Fiberglass Hawaii. |

|

Mark the inserts (since they

are handmade, they are all slightly different, so they need to be numbered,

and their orientation noted!). Cut the holes for the inserts with a router

set to just a smidge deeper than the depth of the inserts (1" for the

Chinooks), to allow for the Epoxy paste. |

|

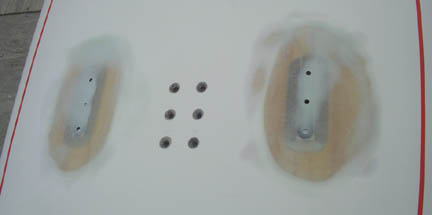

Mix a paste of very slow

Epoxy with Q-Cells, slather the cavities, as well as the inserts all around,

then slowly press the inserts in place. If you

cut the perimeter of the holes to close tolerances, it helps matters along

if you drill small holes between the screw posts to allow excess Epoxy to

escape (which is why the 3-hole inserts in the pictures suddenly appear to

have 5 holes) |

|

Trim the inserts flush, then

grind away the original paint etc for about 1 1/2" all around the new

inserts. Glass over the whole area with at least (3) layers of 4oz cloth. |

|

Grind the cloth nicely, fill

whatever divets plus the cloth weave with an Epoxy paste. |

|

Sand the Epoxy paste nice

and smooth, drill out the screw holes before they disappear from sight

forever!, then apply an Epoxy primer, just to make sure. Let cure, sand to

220 grit. Dust off, then tape off and mask off

anything within 3 feet. |

|

Apply paint - after going

through all this trouble, I like to put on a good paint that will last for a

while without blistering, flaking, and otherwise giving up the ghost

prematurely. With paint, you get what you pay

for. Don't be stingy here!! |

|

Pull tape and masking film

just after the paint has tacked, then let cure thoroughly, at least 24hrs.

Then feather out the paint edges with successively finer wet & dry

sandpaper, such as 400, 600 and 1200grit. For a satin finish such as this

kiteboard, finish with a Scotch "Purple Pad".

Clean up the new insert screw holes and chamfer the edges.

For the Chinook inserts shown, use #10 sheet metal

screws or PT screws to start. Once things have been used a while and gotten

a bit sloppy, you can step up to a #12 size.

Since the inserts are exactly 1" deep, you can in

most cases safely use a 1" long screw, since the foot strap thickness, plus

washer and anti-twist thingies mean that only about 7/8" of the 1" screw

length actually protrudes into the insert.

Never ever use a screw that goes deeper than 1",

since you would create a leak into the EPS core!! |

|

return to Repair Menu |