|

| |

|

Injection |

|

|

At first glance, injection appears to be a handy remedy

for a number of board ailments, easily accomplished with a minimum of

tools in the privacy of your garage. Invariably, though, the process is a

blind one, with us wishing the injected material to go where needed - but

suspecting that it will not necessarily comply with our wishes.

And then there is the compatibility to consider of

the injected material versus the material it is intended to reinforce.

And then there are the problems inherent in

injecting exothermic materials into insulating material with a low melting

point |

|

|

Injection most often comes up in connection with soft

decks. As per the cross-section at right, soft decks are caused by

disintegrated EPS foam, often closely followed by failed PVC sheet foam

(do the crunch test as described on the soft

decks page to see just what ails you) |

|

|

For injected material to make a meaningful structural

contribution, it must have similar mechanical properties to the material

it is intended to reinforce. We are concerned

here with EPS, a soft, spongy material that compresses readily, and

returns almost as readily to its original shape - for a while, anyway.

We are also concerned with PVC sheet foam (Divinycell

etc), that can flex a great number of times without ill effects.

Into all of this you want to inject - Epoxy resin??

with all the flexibility of a brick... Exactly what good could it do?? It

would sit wherever it happened to end up, rigid and unyielding, surrounded

by an ever-flexing collection of materials. They would shortly part

company, to each continue in its own way - with the only noticeable change

being an increase in board weight. |

|

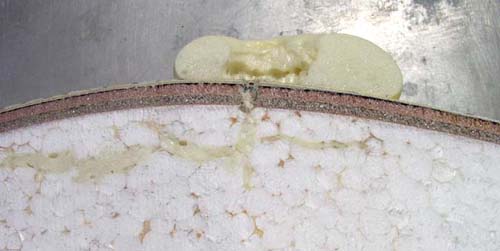

And then there is the exotherm: the Epoxy blob at

right is the result of injecting West System 105/206 (the slow variety)

into a neat 1/8" dia hole I had drilled into the EPS. The Epoxy puddled,

melting a cavity for itself, wherein it sits, doing exactly nothing but

look silly. Judging from the black edges,

this got hot enough to have smoldered! |

|

|

But here is 2-part Marine Urethane foam, injected into another 1/8" hole:

it traveled beautifully into open EPS foam channels, reinforcing same as

it went - and nothing melted in the bargain! While not

having totally the same mechanical properties as EPS, this Marine Urethane

foam is at least similar, with similar density, and ability to flex and recover.

Now THIS makes sense! |

|

|

|

| In order to make sure it goes into all

EPS cavities, I drill 1/8" holes approx 2" apart, start injecting small

batches (10cc admixed) from the rail inboard, then skip those holes that have already

had Urethane foam spill out of them. |

Once mixed, Urethane foam will wait for

no man, so preparation is the key to success. Use a stopper of sorts

(finger, syringe) during foam expansion, to encourage foam migration into

the board. And be prepared for a bit of a mess! |

| Regarding the failed PVC

sheet foam, I have never been able to control Epoxy resin injection well enough to

guarantee a useful glue line (and believe me, I have tried, hoping to be

able to cut my turn-around times). After many experiments I have come to

the conclusion that the only predictably successful repair is replacement of

the PVC sheet foam. So very sorry!

at right the unhelpful injection of

filler I found in the soft deck of a race board |

|

|

back

to Repair Menu |

|